Along with that, Microsoft promises to let you bring those creations into the real world, either using Windows Mixed Reality, or by 3D printing them. We don’t have a HoloLens at the office, but we do have some 3D printers, so we set about assessing these claims the best way we know how — by testing them.

We used to draw

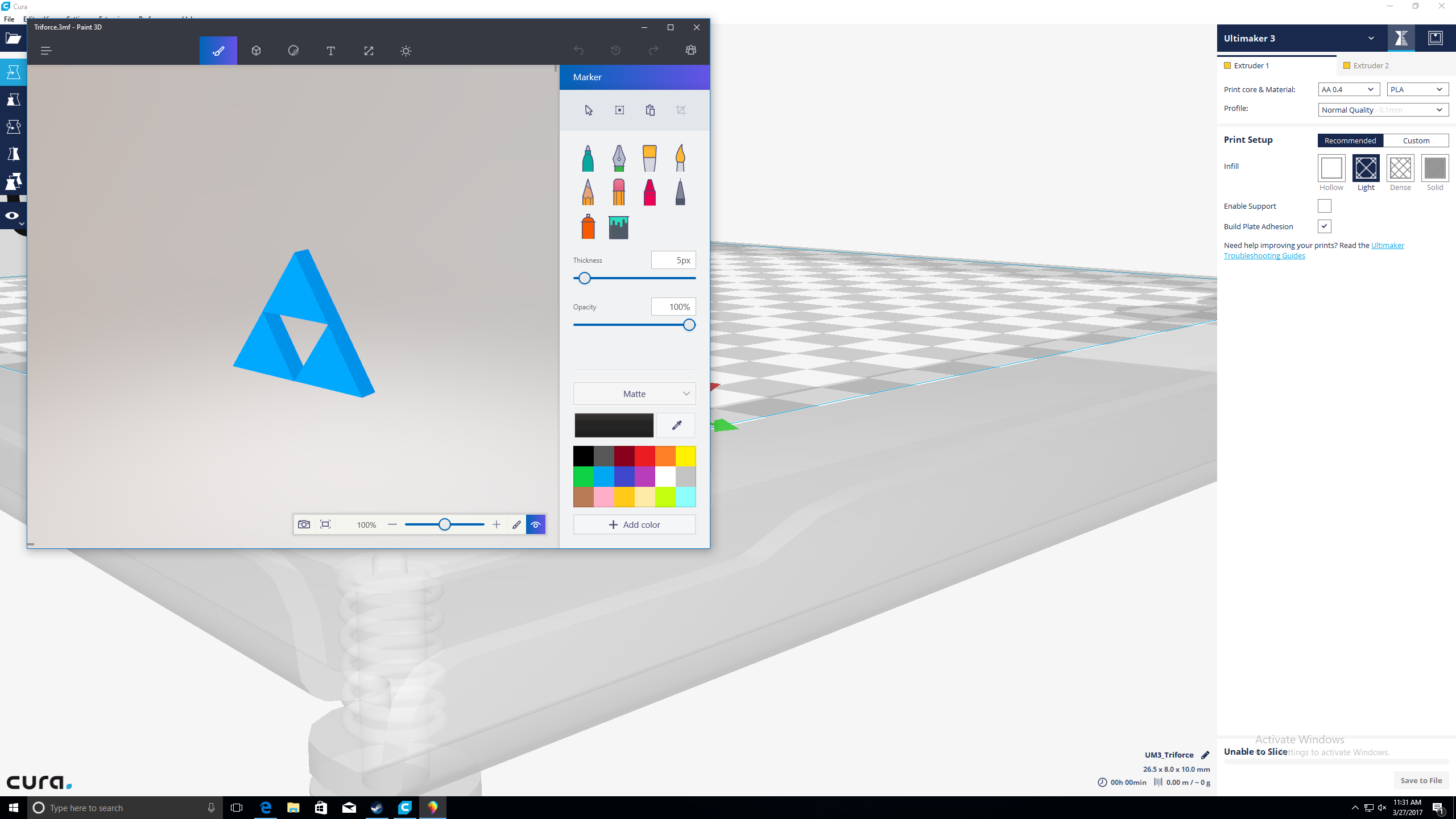

While Paint 3D may have made a turn towards more complex modeling applications, it shares a lot of its UI and menu structure with its older sibling. You have a canvas, at least by default, that acts as a stage for your art, and the tools you would expect from an image editor – pen, eraser, paint bucket, pre-made shapes, and so on. When you select the cone button and draw a triangle, Paint 3D automatically gives it depth, and places it in front of the canvas.

There’s one odd design decision that will stand out, particularly to users already familiar with more advanced 3D modeling systems. In Paint 3D, you only ever edit your project from one direction. By changing to the perspective mode, you can swirl around the object, zoom in and out, and raise or lower the camera level. The moment you click the edit button, however, the perspective will snap back to a front-on view.

That’s not really an issue for single 3D objects, as you can rotate the object in place to re-shape or paint it. As the object count grows, you’ll find you must pull each object out in front of the rest, do any work on it, and then rotate and slide it back into place. Without a rich set of camera controls, tool changing shortcuts, or many hotkeys to speak of, this process quickly becomes tedious.

Oddly shaped

Perspective is far from the only issue with Paint 3D. In general, the drawing and painting tools are quick to make changes permanent. You can draw custom shapes, but the moment you finish they harden into arbitrarily extruded versions of your carefully placed points. With no way of welding multiple objects together, the workflow becomes a tedious loop of exporting and re-saving files. It goes something like this.

After creating a shape at the front of your build, you paint or apply stickers, which have their own problems. Like real stickers, the 3D Paint version can’t be move once applied. Once you’ve slapped it in place, you either must use undo to remove it, or paint over it. Paint isn’t perfect either, but its main issue comes from the perspective problem — If you want to paint anything but the front side of an object, you must rotate the object itself, paint it, then spin it back around.

In Paint 3D, you only ever edit your project from one direction

There’s no way within Paint 3D, at least that we could identify, to weld or join objects together into more complex shapes. After you put a few simple pieces together, you can export them as a single file, then reload them back into Paint 3D as a single model, which you can now only scale or paint as one big chunk.

Scale and precision are also major issues in Paint 3D. It’s tough to create models without any sort of idea of size or ratio to other objects in the build, and Paint 3D offers no help at all. That’s of concern when it comes to 3D printing. There are a lot of fundamental rules that govern successful fused filament fabrication, and Microsoft doesn’t offer any of the tools you need to work within them.

Piles of plastic

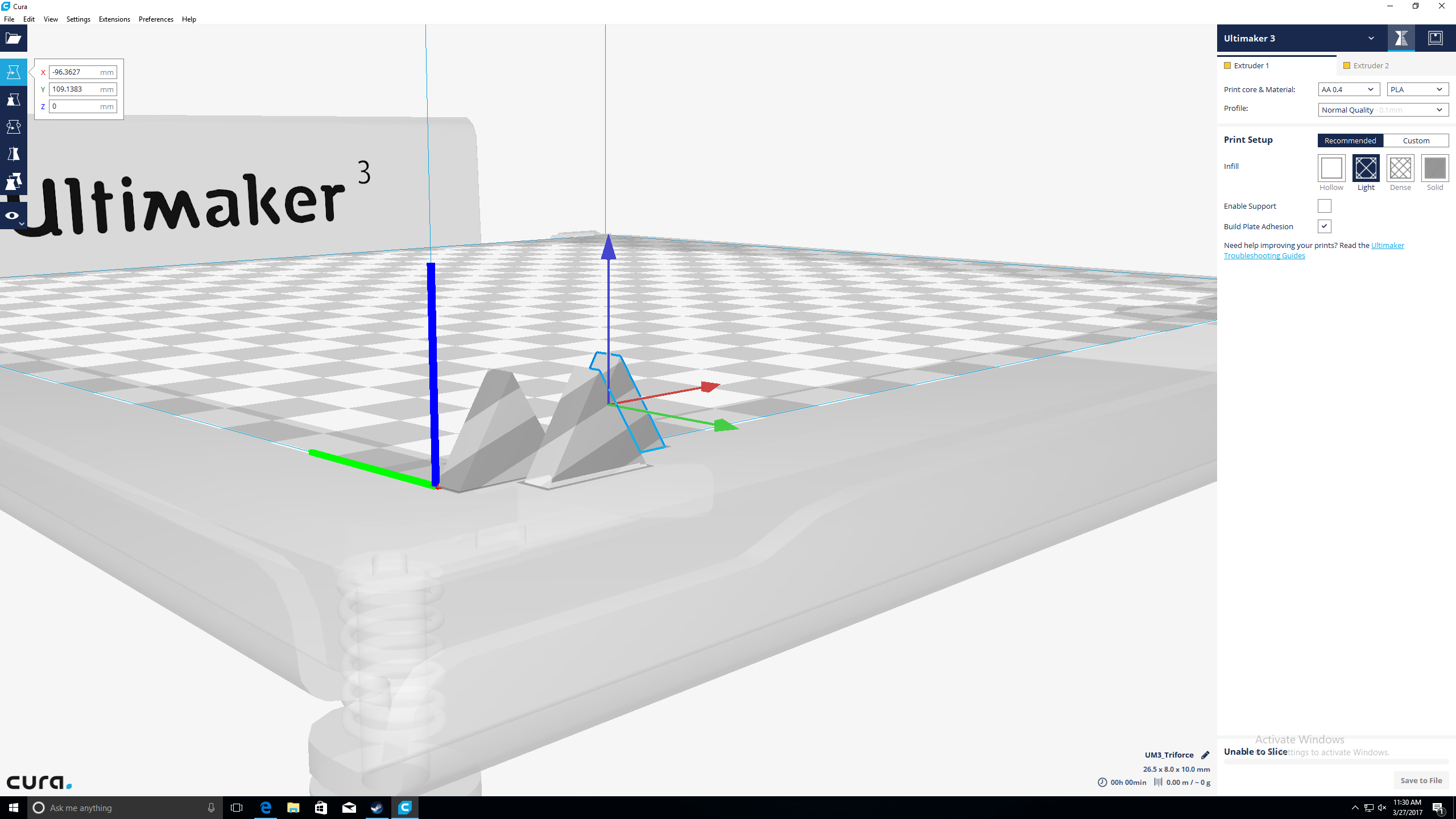

Most, if not all, home 3D printers use a process called fused filament fabrication. It works by melting down plastic filament, then carefully laying down layer after layer of the melted goo. For that to work, you need a flat surface to print on, and you need each layer of your printed object to be smaller than the one before it, or at least, there needs to be no dramatic overhangs, as the filament would simply drop onto the print bed in a plastic mess.

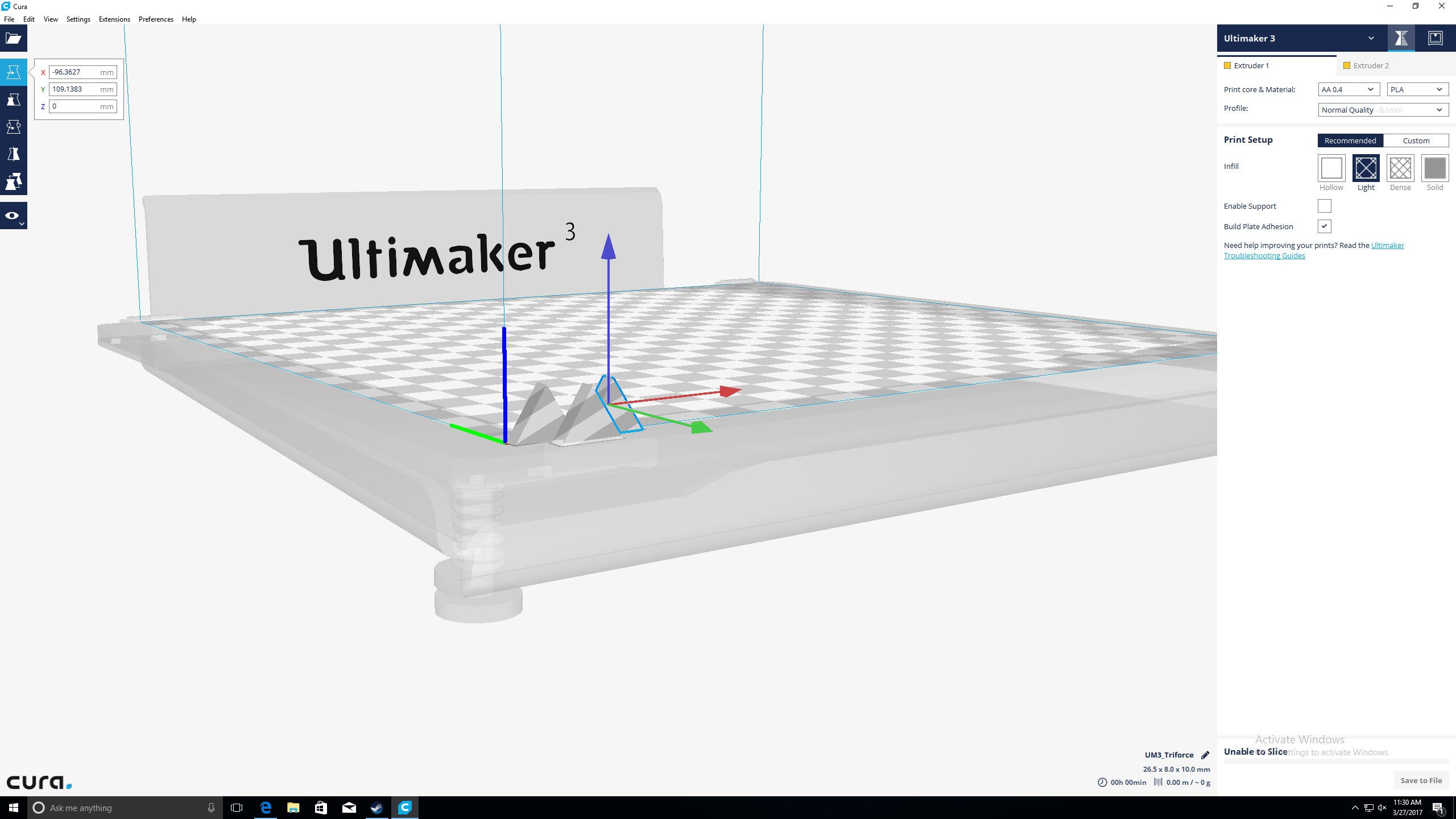

The process for 3D printing an object isn’t terribly complicated to begin with. You take a 3D object from your favorite software and export it as a .obj or .stl file, both of which are simple file types that include only the basic information about the object’s shape. You load those into a slicing program, typically Cura or Makerbot Desktop, and feed it info about your printer. The slicing program takes the object and turns it into gcode, which is essentially a text file telling the extruder on the printer where to move and where to plant material.

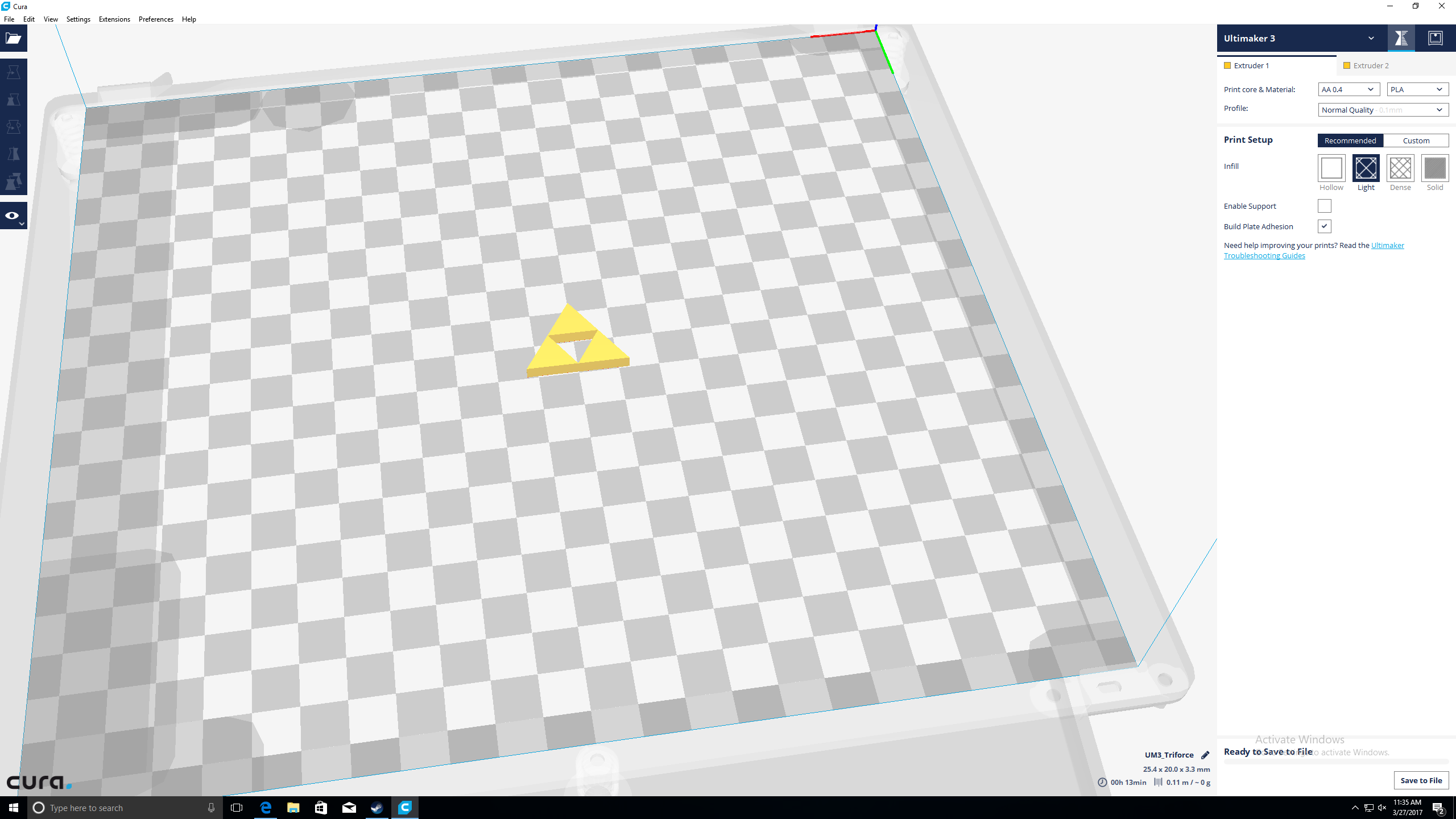

Exporting a 3D object to a file from Paint 3D doesn’t save it as the two most common formats, .obj or .stl, because those file types don’t have any room for color data, which is part of Paint 3D. Instead, it saves a .3mf file, which contains not just shape data, but color data for every piece of the model. When you open it in Paint 3D again, it looks exactly as it did when you exported it, which is a big advantage if you stay within the Paint 3D ecosystem.

Paint 3D feels like a messy-fingered headache, as you wildly swing quick-set concrete toys around inside a cardboard box

Home users typically reach for a slicing program to turn a 3D model into a printable file, and Cura, our favorite application, handles the .3mf file format, at least on paper. It doesn’t know how to place multiple objects together, however, or deal with colors, so you’ll have to do some work once you’ve imported it to whip it into shape for printing. With more complex models, it’s likely you’ll reach for SketchUp, which is easy to use, to prepare any models for final treatment — although you may need an extension to open .3mf files there as well.

The file format choice is more than just Microsoft wanting to make sure your stickers survive. It’s also a signal that Paint 3D models are bound for more expensive commercial machines that can print in any number of colors at once. Instead of printing the item at home, it’s more likely Windows is looking towards a business model where you upload a file to Remix3D or another service, and pay to have it printed out and shipped to you.

A sloppy paint job

When Microsoft first showed off Paint 3D, it came off as more of a diorama maker than a purpose-built 3D modeling application. That’s a fine space to fill, allowing kids to put their favorite shapes and images into little clusters of objects, but Paint 3D doesn’t follow through on that promise either. The best course Microsoft could have taken was making Paint 3D as close to handling clay and posterboard as possible. Right now, it feels like a messy-fingered headache, as you wildly swing quick-set concrete toys around inside a cardboard box.

It doesn’t help that 3D printing requires a massive amount of precision, structural work, and attention to detail — not to mention patience — to work in any form. If Paint 3D let you doodle for a bit and spit out something like what you drew in thermoplastic, it would be enough to call it a success. Instead, Sketchup is still an easier application for that, with easily read specifications, tool icons that demonstrate what they do, and a camera that stays in place while you’re editing. Without the versatile, if basic, set of tools that the original Paint offered, Paint 3D feels like a step into the wrong direction.